FOB Price

NegotiateBrand

-Lead Time

Stock Quantity

CustomizationWarranty

12 monthsSource Areas

Henan , Xinxiang City , Xinxiang CountySupply Ability (Month)

- /Payment Method

| Drive type | ydraulic |

Products

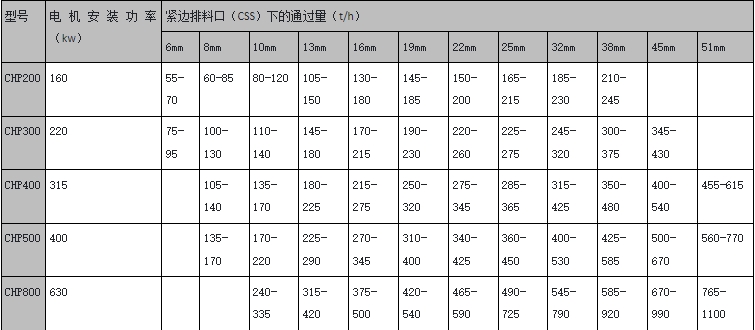

Hydraulic cone crusher is driven by hydraulic pressure, also called hydraulic stone breaker. Hydraulic cone crusher can be divided into multi-cylinder hydraulic cone crusher (CHP series) and single-cylinder hydraulic cone crusher (HCS series) according to the difference of providing hydraulic system. In the specific study of the structure of the cone crusher, we analyse from a certain cross-section of the cone crusher cavity, the dynamic cone will be around the centre line of the fixed cone uniformly back and forth for the rotary pendulum movement. In the process of crushing the material, the ore will be crushed by the huge force to the critical stress of the material to achieve the initial purpose of crushing. During the falling movement of the crushed material, the ore will pass through the cavity of the cone crusher together with the movement of the moving cone under the action of gravity. At a fixed point in the crushing chamber of the cone crusher, the distance between the moving cone and the fixed cone will change periodically with the different opening and closing states.

Working Principle

CHP Series Hydraulic Cone Crusher is driven by the rotation of the electric motor, which drives the belt wheel or coupling, drive shaft and cone to make the eccentric shaft do cyclic rotary oscillation movement under the axis. After the material enters the crushing chamber from the material opening, it is subjected to mutual impact, extrusion, grinding and rubbing by the eccentric shaft and the mortar wall, thus generating the crushing effect. Hydraulic insurance system can be hydraulic support sleeve and fixed cone section out of the fault when the machine over iron failure or bogging phenomenon, greatly reducing the maintenance rate and improve production efficiency.